Stainless Steel Valve

Stainless Steel Valve Specification

- Features

- Corrosion Resistant, Leak Proof, Durable

- Valve Type

- Stainless Steel Valve

- Material

- Stainless Steel SS304/SS316

- Connection Type

- Flanged, Screwed, Socket Weld

- Control System

- Manual Operated

- Valve Size

- DN15 - DN300

- Structure

- Flanged/Buttweld/Threaded

- Sealing

- PTFE, EPDM, or Metal-to-Metal

- Voltage

- N/A (Manual)

- Application

- Industrial, Plumbing, Water, Oil, Gas, Chemical Processing

- Type

- Ball Valve / Gate Valve / Globe Valve / Check Valve

- Power

- Manual

- Pressure

- Up to 16 Bar

- Media

- Water, Oil, Gas, Air, Steam

- Port Size

- 1/2 inch to 12 inch

- Temperature

- -20C to 220C

- Disc

- Stainless Steel

- Pin

- Stainless Steel

Stainless Steel Valve Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

About Stainless Steel Valve

Stainless Steel Valve

- On request, certifications as above

Versatile & Durable Design

The valve is constructed from high-grade stainless steel (SS304/SS316), ensuring corrosion resistance and durability in challenging environments. Available body finishespolished or sand-blastedenhance both aesthetics and longevity, adapting seamlessly to industrial or plumbing installations.

Flexible Installation & Operation

Designed for horizontal or vertical mounting, these valves accommodate quarter-turn or multi-turn actuation. End connections include BSP, NPT, and ANSI flange, while manual operation via stainless steel or aluminum handles offers user-friendly control with secure locking options.

Superior Sealing & Leak Protection

Equipped with PTFE, RPTFE, EPDM, or metal-to-metal sealing, these valves achieve Class VI (bubble tight), Class I, or II leakage rates. Hydrostatic and pneumatic testing verify leak-proof reliability under working pressures up to 16 Bar, matching the stringent standards required in industrial and utility services.

FAQs of Stainless Steel Valve:

Q: How do I choose between polished and sand-blasted body finishes for stainless steel valves?

A: Select a polished body finish for environments requiring a smooth, aesthetic appearance or easy cleaning, such as food processing. Sand-blasted finishes provide a matte surface ideal for industrial settings where abrasion resistance is desired.Q: What industries commonly use these stainless steel valves?

A: These valves are widely utilized in water, oil, gas, air, steam, and chemical processing industries. They are suitable for power plants, plumbing, and general industrial applications where durability and leak-proof performance are essential.Q: When should I opt for a full port versus a reduced port valve?

A: Choose full port valves for applications demanding minimal flow restriction and maximum throughput, such as water or gas distribution. Reduced port valves are suitable when lower flow is acceptable and cost or space savings are needed.Q: Where can these valves be installed, and are mounting options flexible?

A: Stainless steel valves can be installed horizontally or vertically, fitting a variety of piping systems using flanged, screwed, or socket weld connections. This flexibility supports diverse installation environments and space constraints.Q: What testing is performed to ensure valve reliability and leak-proof performance?

A: All valves undergo hydrostatic and pneumatic pressure testing to guarantee leak-proof performance. The leakage rates conform to Class VI (bubble tight) or Class I-II standards, providing assurance for demanding applications.Q: How does the valves fire-safe design benefit industrial operations?

A: The optional fire-safe design prevents leakage of flammable media during high-temperature or fire incidents, protecting facility safety and compliance with industry regulations.Q: What are the advantages of a blow-out proof stem and replaceable seats?

A: A blow-out proof stem enhances operational safety by preventing stem ejection under pressure, while replaceable seats facilitate maintenance, extending the valves service life and reducing overall costs.

Price 4000 INR/ Piece

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Safety Valves Category

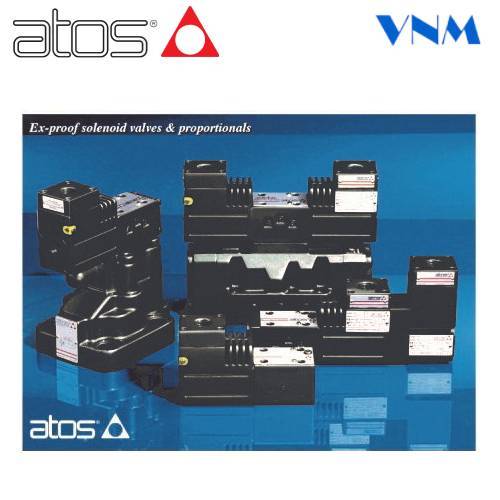

Atos Explosion proof valves

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Valve Size : NG6, NG10 sizes available

Power : Other, Solenoid operated

Application : Industrial automation, hazardous/explosive environments

Control System : Electrical solenoid actuation, available with manual override

Atos Flame proof Valves

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Valve Size : NG06 to NG32 (CETOP 03 to CETOP 16)

Power : Other, Up to 30W (coil power depends on model)

Application : Suitable for explosive and hazardous areas in hydraulic systems

Control System : Electromagnetic solenoid operated

Hydraulic Joysticks

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Valve Size : Standard: 85 mm body diameter

Power : Other, Manual operated (no electrical power required)

Application : Hydraulic control systems for industrial machinery, construction & agricultural equipment

Control System : Manual direct drive, multiaxis proportional control