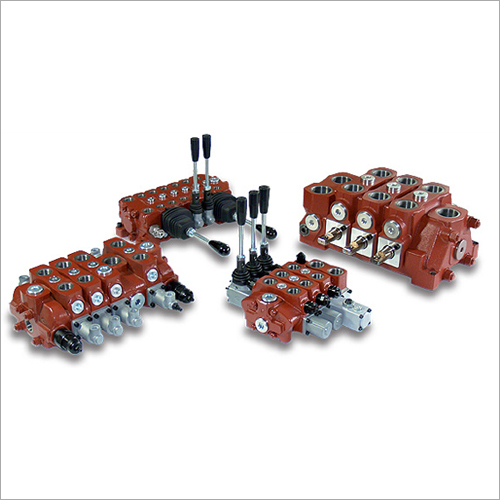

Pilot Control Valves

Pilot Control Valves Specification

- Sealing Type

- EPDM, NBR, PTFE

- Operating Pressure

- 1.5 to 10 Bar

- Efficiency

- High Efficiency

- Connectivity Type

- Threaded, Flanged Ends

- Temperature Range

- -10C to +80C

- Application

- Industrial Automation, Water Treatment, Oil & Gas, Chemical Plants

- Flow Rate

- Up to 150 L/min

- Power Source

- Electric, Pneumatic

- Mounting Type

- Sub-base/Direct Mounting

- Features

- Corrosion Resistant, Compact Design, Low Maintenance

- Accessories

- Solenoid Coil, Manual Override, Connectors

- Body Material

- Brass, Stainless Steel, or Cast Iron

- Type

- Pilot Control Valve

- Structure

- 2/2 Way or 3/2 Way

- Force

- Pneumatic or Hydraulic

- Speed

- High Response Speed

- Voltage

- 12V/24V DC, 110V/220V AC

Pilot Control Valves Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

About Pilot Control Valves

Pilot Control Valves: Uses & Applications

Pilot Control Valves are designed for reliable operation in industrial automation, water treatment, oil and gas, and chemical plants. With robust sealing types and media compatibility for air, water, oil, and gas, they deliver directional control with high cycling efficiency. These valves are best mounted directly or via sub-base, ensuring adaptability in varied environments. For optimal operation, follow recommended procedures for flow rate, pressure, and voltage as per your system needs.

Supply Ability & Delivery Estimate

We guarantee steady supply ability for bulk or customized requirements, with competitive sale price options and detailed valuation on request. Pilot Control Valves are shipped from select India FOB ports, streamlining logistics and reducing wait times. Delivery timelines are quick and predictabletypically dispatched within an estimated 7 to 14 working days, ensuring your operation remains uninterrupted and efficient.

FAQs of Pilot Control Valves:

Q: How do Pilot Control Valves ensure zero leakage during operation?

A: Pilot Control Valves achieve zero leakage (bubble tight) through advanced sealing mechanisms, using EPDM, NBR, or PTFE materials, which maintain tight isolation between media and external environment during every cycle.Q: What benefits do the latest Pilot Control Valves offer in industrial settings?

A: These valves deliver high response speed (<50 ms), corrosion resistance, and exceptional cycle life exceeding 1 million cycles, making them ideal for continuous, low-maintenance operation across industrial automation and process control systems.Q: Where can these Pilot Control Valves be installed within my facility?

A: The valves can be mounted directly or sub-base in various locations, suiting threaded or flanged connections. Their compact design allows integration into process lines, machinery, or control panels in plants, workshops, or remote field installations.Q: When is it recommended to use the Pilot Operated Control Method?

A: A pilot-operated control method is preferred when rapid, precise valve action is necessary, especially in systems requiring swift response to pressure or flow changes in industrial, chemical, water treatment, or oil and gas applications.Q: What is the process for selecting the right model for specific media?

A: Assess the required port size, media compatibility (air, water, oil, or gas), operational pressure, cycle frequency, and desired control structure. Match specificationsbody material, mounting type, and voltageto your system requirements for optimal performance.

Price 4000 INR/ Piece

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Walvoil Category

Diverter Valves

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Sealing Type : Other, PTFE / EPDM / Metal Seated

Force : Other, Manual / Pneumatic / Electric Actuation

Connectivity Type : Flanged / Threaded Connections

Operating Pressure : Up to 10 Bar

Compensated Load Sensing Proportional Valves

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Sealing Type : Other, NBR/Viton Seals

Force : Other, Low actuation force required

Connectivity Type : Standard hydraulic interface

Operating Pressure : up to 350 bar (5075 psi)

Handlevers And Accessories

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Sealing Type : Other, Standard Rubber Seal

Force : Other, Manual Operation

Connectivity Type : Direct Mechanical Connection

Operating Pressure : Ambient