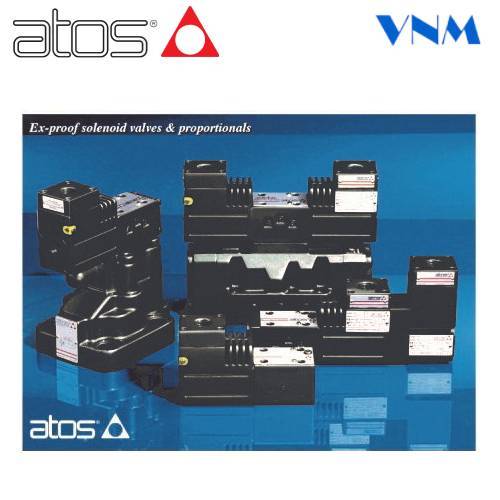

Atos Flame proof Valves

Atos Flame proof Valves Specification

- Material

- High strength cast iron or steel body

- Valve Type

- Directional control valve, poppet or spool type

- Features

- Ex d IIC T6 flameproof coil, ATEX & IECEx certification, water-proof design, high response time

- Control System

- Electromagnetic solenoid operated

- Connection Type

- Threaded or subplate mounting

- Valve Size

- NG06 to NG32 (CETOP 03 to CETOP 16)

- Sealing

- Nitrile (NBR), Viton (FKM), EPDM options

- Voltage

- 24VDC, 110VAC, 230VAC (depending on coil)

- Application

- Suitable for explosive and hazardous areas in hydraulic systems

- Structure

- Direct or pilot operated, solenoid actuated

- Type

- Solenoid operated directional control valve, flameproof enclosure

- Power

- Up to 30W (coil power depends on model)

- Pressure

- Up to 350 bar

- Media

- Hydraulic oil, Mineral oils, Phosphate esters

- Port Size

- 1/4 to 3

- Temperature

- -20C to +60C (ambient)

- Disc

- Hardened steel or alloy

- Pin

- 2 or 3-pin flameproof certified connector

- Operational Life

- Over 50 million cycles

- Protection Class

- IP66/IP67

- Weight

- Varies by model, typically 212 kg

- Manual Override

- Optional lever or push button

- Mounting Position

- Any

- Response Time

- Less than 50 ms

- Operating Fluid Viscosity

- 10400 cSt

- Coil Insulation Class

- Class H

Atos Flame proof Valves Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

About Atos Flame proof Valves

Atos - Flame proof Valves manufactured and supplied by our company can be used in industrial automation systems due to its efficient functioning and robust design. This heavy duty device is designed to control flow rate and pressure. Top-grade alloyed steel and high density ABS plastic is used for the manufacturing of this valve that makes them capable to bear extreme pressure and temperature. It is provided with dimensionally accurate mechanical connectors to rigidly fix pressure hoses. The offered Atos - Flame proof Valves can be delivered to our customers in large quantities with an assurance of fast and safe delivery.Superior Safety for Hazardous Areas

Atos Flame Proof Valves deliver uncompromising safety for environments where explosive gases or vapors may be present. Their Ex d IIC T6 flameproof coil and certifications from ATEX & IECEx make them a prime choice in industries such as chemical, oil and gas, or mining. Integrated with water-proof, heavy-duty housing and high-strength cast iron or steel bodies, these valves provide peace of mind during critical operations.

Reliable and Flexible Hydraulic Control

These directional control valves enable precise modulation of hydraulic fluids, supporting both poppet and spool designs for a range of flow and pressure control needs. Electromagnetic solenoid operation ensures quick switchingless than 50 mswhile optional manual overrides offer operational flexibility. With various port and connection types, installation adapts seamlessly to new or existing hydraulic systems.

Extended Operational Life and Minimal Maintenance

Engineered for durability, Atos Flame Proof Valves maintain their functionality over more than 50 million cycles, significantly reducing downtime and service needs. Hardened alloy discs, superior sealing options, and water-proof design ensure consistent operation, even under demanding conditions. Coupled with easy-to-access manual controls, these valves minimize maintenance interruptions.

FAQs of Atos Flame proof Valves:

Q: How do Atos Flame Proof Valves ensure safe operation in explosive environments?

A: These valves incorporate flameproof enclosures (Ex d IIC T6), ATEX & IECEx certification, and water-proof, corrosion-resistant bodies to prevent ignition of surrounding gases. The design meets stringent international standards for use in hazardous areas, making them suitable for hydraulic systems in chemical, oil & gas, and mining industries.Q: What types of hydraulic fluids are compatible with these valves?

A: Atos Flame Proof Valves are suitable for use with hydraulic oil, mineral oils, and phosphate esters. Sealing options include nitrile (NBR), Viton (FKM), and EPDM, allowing for compatibility with varied media and operational conditions.Q: Where can these valves be installed in terms of mounting positions?

A: Installation is highly flexible since Atos Flame Proof Valves can be mounted in any positionthreaded or subplate mountingmaking them adaptable to both new projects and retrofits in existing hydraulic control setups.Q: What is the operational life and maintenance requirement of these valves?

A: Each valve is designed for over 50 million cycles, significantly reducing the need for frequent maintenance. Hardened steel or alloy discs, durable seals, and robust material construction help maintain reliable performance over extended service periods.Q: How does the manual override function work, and when is it used?

A: An optional manual overridevia lever or push buttonenables manual operation of the valve during power loss, maintenance, or emergency situations. This feature ensures critical hydraulic systems can continue to function even if electromagnetic control is unavailable.Q: What are the benefits of the high response time in Atos Flame Proof Valves?

A: With a response time of less than 50 milliseconds, these valves offer rapid switching to enhance process efficiency, safety, and precision control, particularly important in automated hydraulic systems and emergency shutdowns.Q: What power options and connector types are available for coil operation?

A: Coil operation can utilize 24VDC, 110VAC, or 230VAC power supply, depending on model choice, and connects via 2 or 3-pin flameproof certified connectors, ensuring safe electrical integration in hazardous areas.

Price 4000 INR/ Piece

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2-10 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Safety Valves Category

Hydraulic Joysticks

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Disc : Hardened steel movement disc

Material : Highstrength engineered alloy

Sealing : Synthetic rubber Oring and gasket system

Temperature : 25C to +80C

Atos Explosion proof valves

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Disc : Stainless steel or brass (depending on model)

Material : Aluminum body with surface treatment explosionproof coil

Sealing : NBR or FKM (Viton) seals

Temperature : 20C to +60C

Stainless Steel Valve

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Disc : Stainless Steel

Material : Stainless Steel SS304/SS316

Sealing : PTFE, EPDM, or MetaltoMetal

Temperature : 20C to 220C